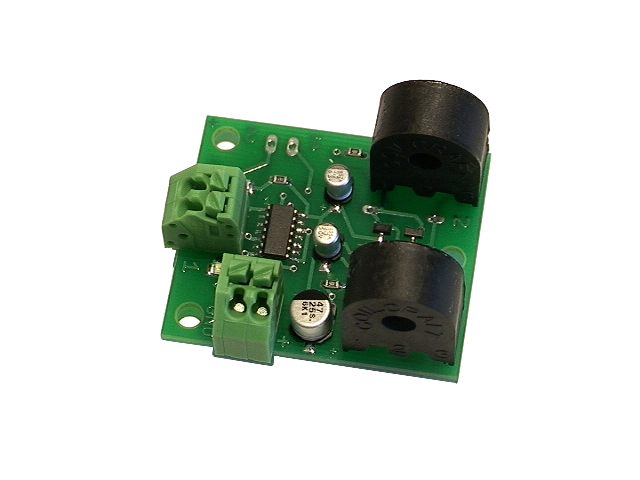

The DBD22 is a dual block occupancy detector. It provides complete isolation from the track by using small transformer type sensors. This also means there is no drop in track voltage as there is with sensing diodes. The DBD22 is designed to work well with the signal controllers.

MSRP – 23.95 USD

Manual in PDF format – 180K

Board size: 1.5″ X 1.8″

Operation:

The DBD22 is capable of sensing current in two isolated sections of track called blocks. This provides for detecting the presence of locomotives or other rolling stock that draw current from the track.

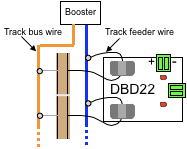

The track feeder wire for one rail of the block is passed through the hole in the sensor (see diagram below) before connecting the feeder to the track. When the current in the feeder going though the sensor reaches the trigger level, the output is turned on and the LED lights showing the block is occupied. Passing the feeder though the sensor more than one time will increased the sensitivity. However, this is NOT recommended because the maximum sensor current specification will be greatly reduced.

Locomotives and lighted cars draw enough current to trigger the DBD22. In order for other rolling stock to draw current, resistive wheel sets will have to be added. For HO scale, one 4.7K ohm resistive wheel set will work per car. If you want to use 10K resistive wheel sets you will need two wheel sets per car.

Duty track can cause intermittent current flow. A built in filter keeps the DBD22 from rapidly turning off and on if the current flow is interrupted. Additional, there is a small amount of hysteresis so that small changes in track current near the trigger point do not cause the DBD22 to turn off and on. The filter keeps the output on after a train leaves the block for a short period of time. This time is typically about 1 to 2 seconds. The amount of track current has an effect on this time.

Since the DBD22 does not use diodes to sense track current there is no drop in track voltage. This allows you to “double sense” a block. For example, suppose you want to add a grade crossing with gates and flashers to a section of track that already has a diode sensing block detector. The block could be cut into three smaller blocks to detect traffic on each approach and island blocks. DBD2s can be used for the three new blocks with out interfering with the operation of the original detector or causing an additional track voltage drop. See the SIC24e signal and indicator controller for information on implementing a grade crossing.

Specifications:

Operating voltage: 5 to 15 volts DC

Typical operating current (unoccupied): 3 ma @ 5 volts, 8 ma @ 12 volts

Typical operating current (occupied): 8 ma @ 5 volts, 20 ma @ 12 volts

Maximum load per output: 150 ma

Typical trigger current: 3 ma @ 5 volts, 6 ma @ 12 volts

Maximum sensor current: 5 amps w/one pass of feeder wire