The purpose of a circuit breaker is to keep a booster from shutting down because of a current overload or short and thus shutting down the whole section of the layout the booster is powering. Normally there would be at least two circuit breakers for each booster. Each would protect a section of track. If there is a short in one section of track then trains can still operate in the other section(s).

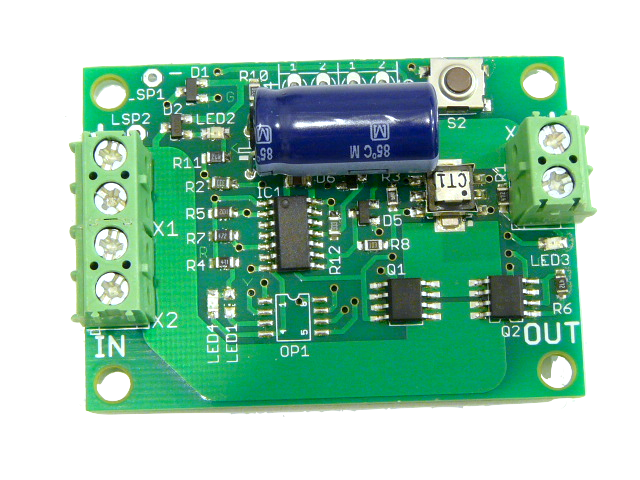

The DCCBreak is designed to provide the function of a circuit breaker. It also has some features that help to start “difficult loads” that may otherwise cause the booster problems. One type of “difficult load” is caused by the capacitors used in some decoders, typically with sound. When power is first applied to a capacitor, it appears like a short until it is charged.

If there are several DCCBreaks on the layout, they can be programmed so that each has a different turn on time after the booster turns on. This prevents the booster from experiencing the total layout load current at power on.

The output of the DCCBreak can be turned on and off by issuing a turnout (switch) command or by the control input. This can be useful if you do not want sections of track to be powered all the time. Additional it can be programmed so that when booster power is turned on the DCCBreak does not turn on it’s output until commanded.

MSRP – 39.95 USD

Manual in PDF format

Board size: 2.25″ X 1.62″

Features:

• Short and over current protection

• Adjustable shutdown current level, approx. 5 amp max

• 4 amp continuous operation

• Very low track voltage drop

• Remote on/off control

• Custom programmable turn on sequence